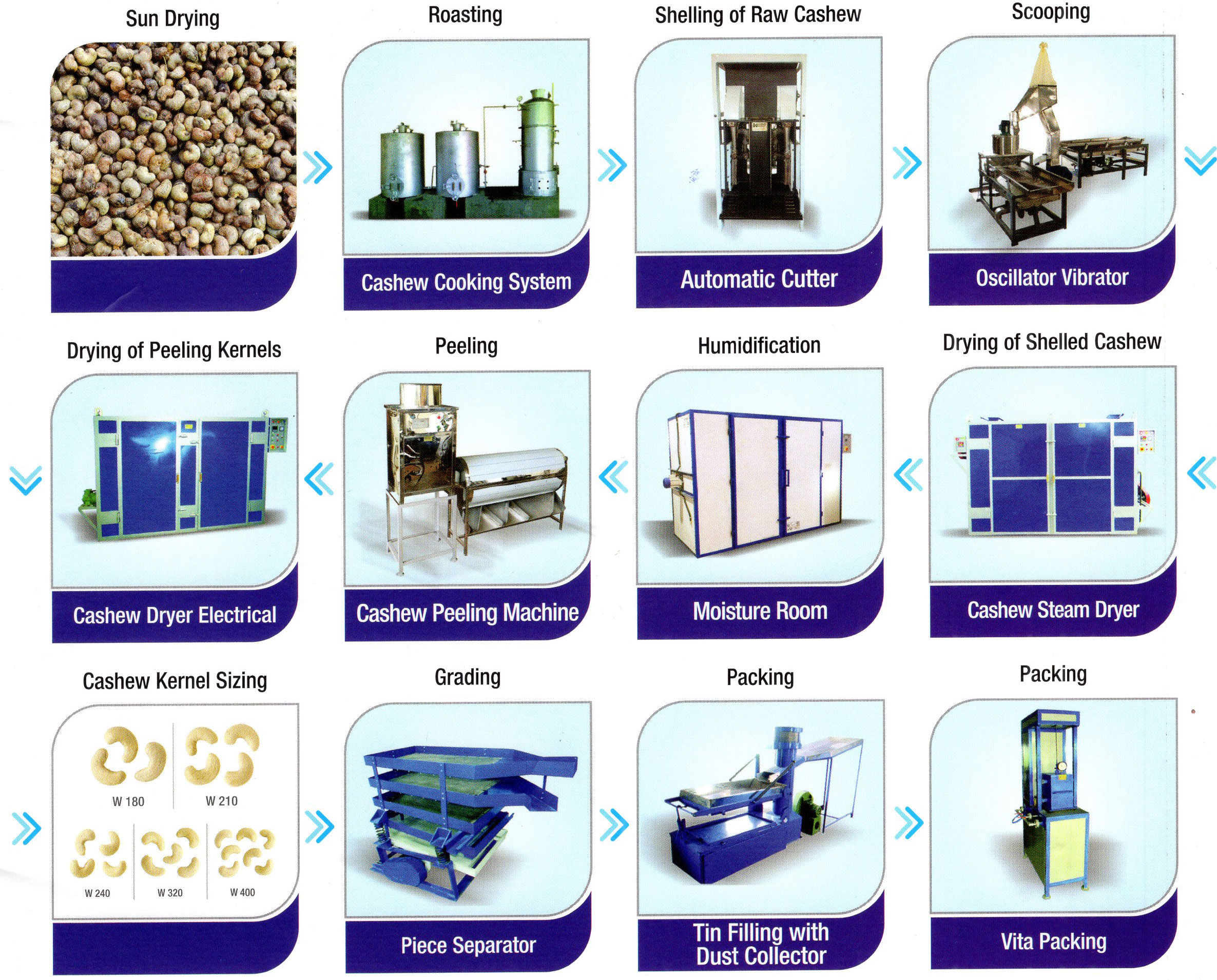

- Sun Drying: Drying raw cashew nuts under sunlight to reduce moisture content.

- Roasting: Steam cooking to make shelling easier and preserve kernel quality.

- Shelling: Automatic cutting of shells to separate whole kernels safely.

- Scooping: Separating kernels using a vibrator and scooping mechanism.

- Drying of Shelled Cashew: Reduces moisture to aid in easy peeling.

- Humidification: Reintroducing moisture for better peeling quality.

Cashew Processing Chart

We are Manufacturer, Supplier, Exporter of Machinery for Cashew Cooking System, IBR Boilers, Baby Boilers for Cashew Cooking from Kudal, Sindhudurg, Maharashtra, India.

- Peeling: Machine-assisted peeling of kernels with minimal damage.

- Drying of Peeled Kernels: Final drying before grading and packing.

- Cashew Kernel Sizing: Sorting kernels by size: W180, W210, W240, W320, W400.

- Grading: Piece separator for broken and whole kernel grading.

- Tin Filling: Dust-free, automated tin filling for large-scale packaging.

- Final Packing: Retail-ready packing with Vita packing machine.